Construction's ongoing journey to net zero

Automating Concrete Construction (ACORN) is a collaborative research project between the University of Cambridge, University of Bath and University of Dundee, and includes a number of CSIC investigators and researchers. The project aims to improve whole-life construction sector sustainability and productivity by creating a culture that takes a fresh, holistic approach to the manufacture, assembly, reuse, and deconstruction of concrete buildings, leading to a healthier, safer, built environment. ACORN, which began in early 2019, continues through 2021 and aims to deliver a prototype structure that will act as a full-scale demonstrator for the research.

Categorising material efficiency in construction

ACORN researchers have identified a clear need for impactful and cost-effective actions to reduce overdesign and improve material efficiency if the construction industry is to achieve net zero carbon targets by 2050.

Until recently, much of the research and innovation on sustainable construction has brought focus to the operational emissions associated with a building, particularly on improving thermal performance. However, there is increasing recognition that capital emissions, those emitted during the manufacture of construction materials and those embodied in the materials themselves, are of similar importance.

Buildings and construction are responsible for 40 per cent of global energy-related CO2 emissions, and cement production is a significant contributor. Recent reports (1,2,3,4) make various suggestions of how to reduce carbon, including policy and public procurement changes, carbon capture and storage, alternatives to Portland cement and demand side measures.

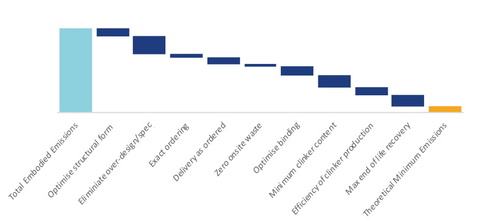

The ACORN team has categorised opportunities for material efficiency by stage of construction as shown in Figure 1 and expanded on below:

- Structural form: including the choice of grid size and using lengths of span greater than required

- Overdesign: plans specify more material than required for structural purpose, for example prismatic beams

- Over-specification of structure: designed for loads greater than experienced

- Over-specification of materials: materials chosen with greater strength than required

- Over-ordering: to avoid running out

- Over-delivery: excess quantity or specification than ordered, for example concrete that is stronger than needed

- Onsite waste: unused materials

- Over-binding: concrete with same strength performance but excess binder index

- Excess clinker (solid material produced in manufacture of cement): concrete with same binder index, but a greater proportion of clinker than required

- Efficiency of clinker plant: clinker produced at a plant without the best available technology

- Efficiency of clinker production: clinker produced while plant is operating below best observed performance

- End of life recovery: emissions resulting from (or mitigated by) treatment of waste at end of life.

The potential for improvement varies, depending on material source, construction stage and process. According to estimates (5) one of the biggest opportunities is in the overdesign category, where waste can be as high as 50 per cent. Beams are often stronger than needed, and design can be led by labour costs rather than minimum material consumption. The ACORN project seeks to address this significant material reduction, and therefore carbon reduction, opportunity by using material only where needed to support the load.

In total, the potential percentage reduction for all categories could be more than 90 per cent, if inefficiencies from every stage of design to construction are eliminated. Further research is needed to confirm these estimates and develop methods to achieve them. The ACORN team will be collaborating with a number of other research groups over the next 18 months to investigate other types of construction project and quantify the losses more precisely. These include investigations into decarbonising precast concrete in conjunction with the Centre for Industrial Sustainability, decarbonising infrastructure projects as part of a collaboration with Expedition Engineering, and improving material flow data gathering in construction in conjunction with Costain.

Contact CSIC Investigator Dr John Orr

Team Dr John Orr; Professor Tim Ibell (Univesity of Bath); Dr Paul Shepherd (University of Bath); Dr Ajith Parlikad; Dr Saverio Spadea (University of Dundee); Dr Robin Oval; Dr Daniel Summerbell, Mrs Diana Thomas-McEwen

For more information about the ACORN collaboration see the website automated.construction

Download the full case study here

References

1 Material Economics The Circular Economy: A Powerful Force for Climate Mitigation, https://materialeconomics.com/publications/the-circular-economy-apowerful-

force-for-climate-mitigation-1

2 Lehne, Preston 2018 Making Concrete Change, Chatham House Report, https://www.chathamhouse.org/sites/default/files/publications/research/2018-06-13-

making-concrete-change-cement-lehne-preston.pdf

3 BIS 2010 Estimating the Amount of CO2 emissions the Construction Industry can influence

https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/31737/10-1316-estimating-co2-emissions-supporting-lowcarbon-

igt-report.pdf

4 CEMBUREAU 2020 Cementing the European Green Deal https://cembureau.eu/media/kuxd32gi/cembureau-2050-roadmap_final-version_web.pdf

5 Moynihan Muiris C. and Allwood Julian M. 2014 Utilization of structural steel in buildings