Inside concrete

This project will generate new data on concrete to enable engineers to make resource-efficient decisions to support the longer-term goal of creating more sustainable structures. Concrete is associated with high carbon dioxide emissions – construction accounts for nearly half of the UK’s carbon emissions, and cement/concrete manufacture alone for four to eight per cent of global CO2 emissions [1]. This project seeks to mitigate future inefficiency by capitalising on improved concrete performance data.

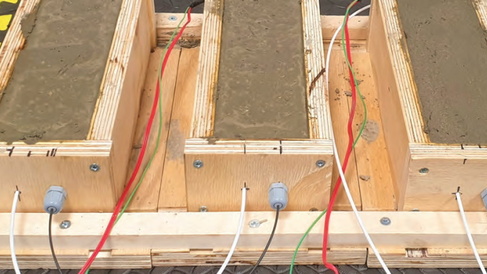

Researchers are investigating fibre optic sensor (FOS) systems embedded in concrete to better understand performance. FOSs allow a continuous collection of data along the fibre length instead of at single pre-selected measurement points as would be obtained with traditional temperature or strain sensors. This enables a better evaluation and assessment of the integrity of a concrete structure. For instance, the temperature development in fresh concrete during hardening can be used to infer the concrete strength gain over time and local strain increases, which can be an indicator of crack formation, can be identified anywhere along the FOS sensor.

Current FOS systems have several limitations including a lack of interpretation models for an in-depth understanding and difficulties in meeting different stakeholder priorities. Professor Janet Lees, who leads this project, chaired a session at the 2019 CSIC Partner Strategy Day with industry colleagues considering how to make better predictions of concrete strength based on early-age measurements. Topics discussed included the need to reconcile in-situ concrete quality with the original specification which requires better confidence in concrete quality at the early stages of the curing process. The chemical reaction between cement and water that binds sand and gravel together to make concrete takes typically 28 days to reach its design strength. Controlling the moisture content and the temperature of new concrete for the first several days through curing is essential to ensure the desired structural integrity. This project is a step forward in harnessing the potential of FOS systems to make better predictions of concrete quality and strength during the curing process.

By casting continuous FOS sensors into fresh concrete, data will be captured as the concrete hardens. Collecting and analysing this data enables an evaluation of the in-situ versus designed properties. As a result, future concrete mixtures and structural designs can be optimised. For example, if a concrete mixture develops a higher strength than intended then either the concrete mixture can be adjusted to reduce the cement content and hence CO2 footprint, or the structural element can be redesigned to use less material thereby leading to a lower embodied carbon. The information can also support more efficient construction programmes including the timing of formwork removal and first loading. Shorter construction times can also lead to reductions in resource consumption.

The experimental programme is being conducted within the University of Cambridge’s state-of-the-art National Research Facility for Infrastructure Sensing (NRFIS) and is exploiting NRFIS equipment to achieve the research objectives. The enhanced data will lead to new understanding for the more efficient utilisation of concrete to thereby reduce the CO2 impact.

Contact: CSIC Investigator Professor Janet Lees

Team: Professor Janet Lees; Dr Marcus Maier

Download the full case study here

[1] https://www.chathamhouse.org/sites/default/files/publications/2018-06-13-making-concrete-change-cement-lehne-preston-final.pdf