Developing new analyses to estimate seabed cable fatigue life

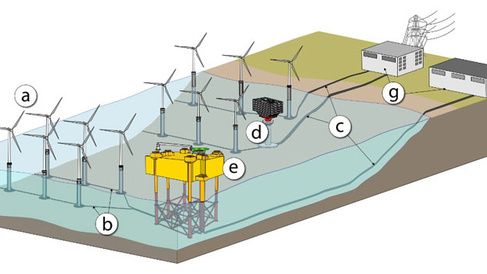

The UK offshore wind sector is a global leader and integral to generating clean electricity helping to decarbonise the economy and contributing to global efforts to tackle climate change. Cable stability, and its impact on fatigue life of the cables, is of increasing concern for the resilience of wind farm energy production in the UK. In this project, CSIC is carrying out experimental validation of models for fatigue life of the cables and developing new instrumentation to provide better estimations of fatigue damage and residual life of cables used in offshore wind farms (see Figure 1).

Figure 1: Main components of an offshore wind farm: (a) Wind turbines; (b) Collection cables; (c) Export cables; (d) Transformer station; (e) Converter station; (f) Meteorological mast; (g) Onshore stations (after Rodrigues et al. 2016)

The importance of better estimation of fatigue life for offshore cables

Offshore cables are usually laid in a trench, but where they connect to other elements of the wind farm infrastructure, they must emerge from the trench to the connection point. As they emerge from the trench, they are exposed to buffeting by the ocean currents, which can cause movement and ultimately fatigue and failure. Cable replacement is costly, as is the impact of cable failure on operations. Therefore, accurate fatigue life estimation can reduce cost through avoidance of early replacement, while avoiding the disruption and cost of failure.

Modelling fatigue life

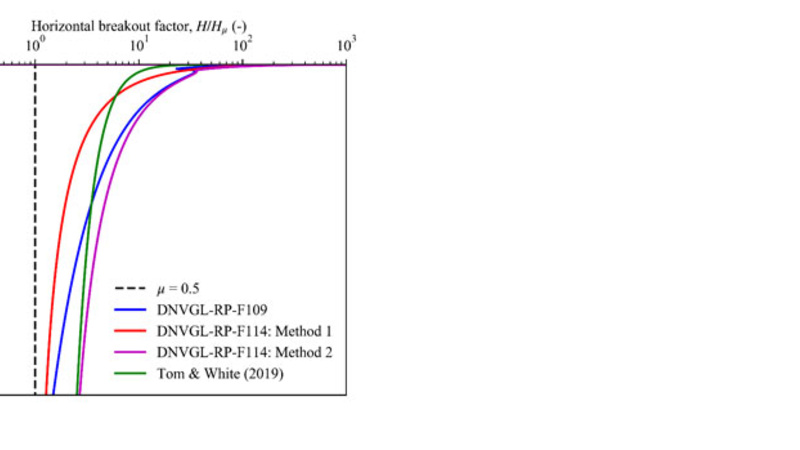

In order for the cable to move, the force on it must be sufficient to move both the cable and the sediments it is emerging from. This is called the ‘horizontal breakout force’, H. Current numerical modelling techniques often assume the cable is restrained on the seabed by simple friction, often with a coefficient of friction, μ, of 0.5. This simple approach implicitly ignores the beneficial effect of any partial embedment on cable stability when such a model is incorporated into finite element analyses (FEA) in order to predict fatigue life.

Alternative cable-seabed interaction models calculate H by taking account of partial embedment. In Figure 2, the black dotted line shows the model for H if μ is constant at 0.5, and if the surrounding sediments are having no effect in restraining the cable. In fact, as the cable embedment increases, the breakout force will increase significantly. The curved lines show various alternative models for this, developed both a-priori and from some limited experimental observations. At low vertical force per unit length (the conditions most relevant as fluid flows laterally past the cable generating lift and reducing the effective weight of the cable) these can give estimates of H that increase by a factor of 50-100. Utilising simple friction erroneously in FEA analysis can result in overly conservative estimates of fatigue life, resulting in early replacement of cables and high maintenance costs. However, it is not clear which of the alternative models is most appropriate, hence, it is important that we assess this through rigorous experimental verification, both in the laboratory and in the field, if possible.

Figure 2: Various models of horizontal breakout factor for a partially buried cable (embedded to half the cable diameter) including: DNVGL-RP-F109, DNVGL-RP-F114 and Tom & White (2019)

Current work and next steps - CSIC research in this area is focussing on:

(i) experimental validation of cable breakout models, such as that proposed by Tom & White (2019), using small scale models

(ii) assessing the impact of incorporating such models into the FEA of cable stability in collaboration

(iii) development of a prototype fatigue damage warning system using fibre-optic technology.

References:

- Rodrigues, S., Restrepo, C., Katsouris, G., Pinto, R.T., Soleimanzadeh, M., Bosman, P. and Bauer, P. (2016). A multi-objective optimization framework for offshore wind farm layouts and electric infrastructures. Energies 2016, (9), 216: 1-42. doi:10.3390/en9030216.

- Tom, J. G. & White, D. J. (2019). Drained bearing capacity of shallowly embedded pipelines. Journal of Geotechnical and Geoenvironmental Engineering, 145(11). Ahead of print. doi: 10.1061/(ASCE)GT.1943-5606.0002151

- Det Norske Veritas (2007). DNVGL-RP-F109: On-bottom stability design of submarine pipelines. Available online. Det Norske Veritas (2017). DNVGL-RP-F114: Pipe-soil interaction for subsea pipelines. Available online.

Contact: CSIC Investigator Dr Sam Stanier

CSIC team: Dr Sam Stanier, Professor Giulia Viggiani, Maria Chalakatevaki

Industry team: Dr Andrew Lennon, Cura Analytical