Monitoring of under-reamed piles during tunnelling interception using distributed fibre optic sensing

The Transport for London Bank Station Capacity Upgrade (BSCU) project is reconstructing one of the busiest interchanges on the London Underground network. The tunnelling and underground excavation works commenced in 2016 and excavated their way around a ‘rabbit warren’ of existing tunnels and beneath many significant buildings in the City of London. An extensive instrumentation and monitoring programme was established to safeguard existing infrastructure assets and buildings.

The unprecedented pile interceptions required at the Princes Court building won the 2019 BGA Fleming Award. This eight-storey two-level basement building, owned by The Worshipful Company of Grocers, was built in the 1970s and is supported on 25 large diameter unreinforced under-reamed piles in London Clay. The sprayed concrete lining (SCL) tunnelling fully intercepted four under-reamed piles. The interception strategy involved cutting piles just below tunnel crown and, while temporarily unsupported, constructing a reinforced concrete permanent load transfer structure around the tunnel for each pile. Fibre optic monitoring was installed in existing piles to measure pile response due to tunnelling and interception and to enable verification of design assumptions.

The innovative use of fibre optics to successfully verify modelling predictions of an unprecedented tunnelling pile interception again demonstrates the versatility of this technology in engineering.

Chris Barker, Associate Director at Arup. Technical Advisor to The Grocers

Innovation and collaboration

Working with Dragados, an Abaqus 3D finite element (FE) geotechnical substructure model, which included the under-ream piles, raft slab, building basement and all tunnel excavation sequences was created by consultant Dr Ali Nasekhian and team at Dr Sauer & Partners Ltd. This model was coupled with a Strand7 3D super-structure model from Robert Bird Group to predict pile foundation and building response to staged tunnelling excavation.

At basement slab level, the tops of the under-reamed piles were instrumented with settlement monitoring studs fixed into the concrete slab above each pile position. At tunnelling level, reflective monitoring targets were installed on the pile shafts above and below the cut level as soon as the pile shaft was exposed (Figure 1). This conventional type of monitoring of the intercepted piles before and after cutting recorded the top and bottom pile displacement from exposing the pile, but not the pre-exposure displacement of the base of the pile nor the response down the length of the pile.

To fully capture pile behaviour due to tunnelling and interception, distributed fibre optic sensors (DFOS) were used to measure the axial strain over the length of the piles during interception and other construction activities. The use of fibre optics to measure strain in new piled foundations is a well-established method and transferring this to the monitoring of existing piles has proven successful. It is the least invasive and only viable method for spatially continuous axial strain measurement where access is limited.

CSIC was brought in by the project team as experts in this field and applied this method by inserting fibre optic sensing cables into two of the 50-year-old under-reamed piles (one intercepted pile and one non- intercepted pile). The piles were cored at 100mm diameter from basement level to depths of 18.9m and 25.3m respectively. A temperature and a strain cable, pre-spliced to form two parallel lines, was lowered to the bottom of the pre-cored boreholes using a spherical weight to overcome buoyancy and keep the cables under tension when grouting (Figure 2). After installation, the cables were connected in a single circuit to a Brillouin Optical Time Domain Analysis (BOTDA) spectrum analyser located in the plant room of the basement.

Figure 1: Exposed under-ream pile prior to cutting (TfL)

Figure 2: Fibre optic sensing cables being lower into cored pile

The under-reamed piles were monitored during tunnelling, pile interception/nibbling, support installation and post construction for over eight months in order to quantify the effect of these activities on pile performance.

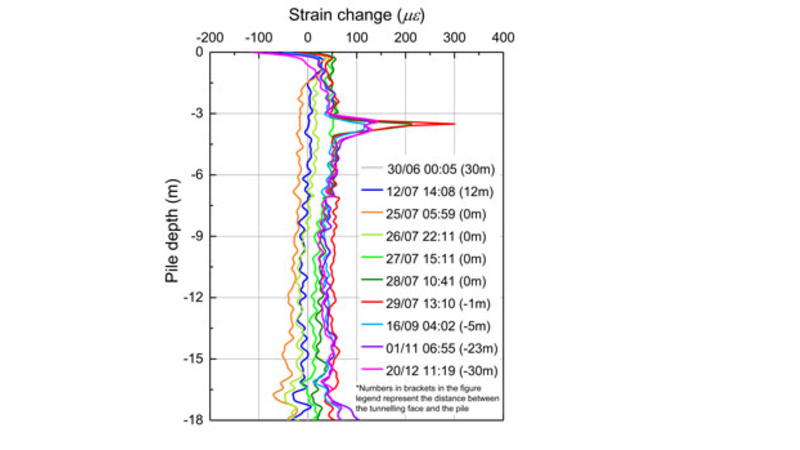

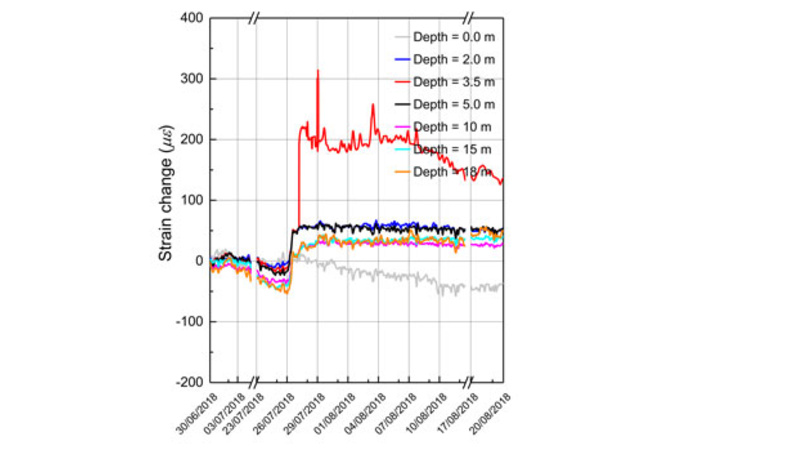

The strain profiles and strain changes at selected vertical locations are presented in Figures 3 and 4, respectively, for one of the fully intercepted piles. There was little change in strain until the tunnel excavation reached the pile, at which point the axial strain increased all along the pile. This was followed by a sudden development of localised strain at the depth of 3.5m two days later. This localised strain had however halved within two weeks and is consistent with the presence of a short reinforcement cage down to this depth. The strain increase from pile interception to the load transfer structure completion measured an overall pile length extension of 1.3mm, which compared with 3 to 4mm measured by the conventional pile instrumentation.

Figure 3: Strain profile during tunnelling and pile interception

Figure 4: Strain changes at selected vertical locations in the pile

Conclusion

This project may mark the first time this fibre optic monitoring method has been successfully used in piling interception during tunnelling. The conventional monitoring method would have been to measure the basement settlement at pile positions with studs, and measuring movement of the pile base by coring the pile and installing a rod extensometer. However, rod extensometers would only record displacement at discrete locations rather than at close intervals as with the fibre optics. It is not thought traditional instrumentation methods would have limited the pile interception solution, however more piles would likely have been instrumented and monitored. By installing innovative fibre optics and recording pile behaviour over the full pile length and at frequent time intervals, a clear picture of how the piles were responding to the advancing tunnel and pile interception gave much better confidence that the building was responding as predicted.

As our urban cities become even more connected with new infrastructure tunnels, there will likely be further opportunities for such smart fibre optic piles to provide a robust and reliable instrumentation monitoring method. There can also be ongoing benefit for such monitoring systems if it provides a means by which existing foundation structures can be reused.

The installation and use of fibre optic instrumentation to measure temperature and strain successfully verified the pile performance made in the design of the pile interceptions at Princes Court. Four of the Princes Court pile foundations are now permanently supported onto reinforced concrete load transfer structures around the new southbound Northern Line tunnel. Two of the 50-year-old piles retain the fibre optic instrumentation and have now become smart fibre optic piles which are available to inform future performance during multiple demolition and construction phases for the Princes Court site.

CSIC team: Dr Cedric Kechavarzi, Dr Xiaomin Xu

Industry partners: Geocisa, Epsimon, Arup and Transport for London