Optimising the design of sprayed concrete linings

This innovative project presented an opportunity for CSIC to collaborate with industry partners Crossrail and Mott MacDonald to use fibre optic cables to observe and monitor the behaviour of sprayed concrete linings (SCL), a technique used to construct the station tunnels on the Crossrail project. The results demonstrate how a distributed fibre optic sensor (DFOS) system can be an effective tool for understanding the structural behavior of SCL, which leads to a better understanding of key design parameters to inform and improve future SCL design.

SCL at Liverpool Street station

The project aimed to gather data on the behaviour of SCL during breakout and excavation of the cross passage junctions in the tunnels at Liverpool Street station. The goal was to produce reliable field data to investigate the accuracy of the 3D finite element models used to design the cross-passage junctions. In particular, the response of the reinforced thickening layer of SCL added at the tunnel enlargement chambers at cross-passage junctions was investigated with the aim of finding new techniques to save time and money.

DFOS installation

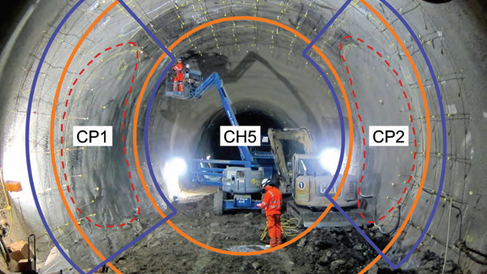

CSIC embedded a DFOS system within the thickened SCL in enlargement chamber CH5 (Figure 1 – download the full case study to see the figure) at two cross-passage junctions, CP1 and CP2 (Figure 2 – pictured above), in order to monitor the changes in the continuous strain profile that occurred in the tunnel lining during the excavation. The distributed nature of the strain measurements obtained from the DFOS system made it possible to reconstruct the strain map in the tunnel lining during every stage of the cross-passage excavations, with unrivalled spatial detail. This information was used to compare the predicted structural behaviour obtained from the finite-element models with the true performance of the tunnel lining.

Understanding SCL performance with smart data

Data collected indicated that the load redistribution within the tunnel SCL during the cross-passage excavation was localised and significant increases in strain were limited to a relatively small distance from the cross-passage openings (1 - 2m). This is considerably smaller than the extent of the thickening SCL. These findings suggest that the benefit of the thickening SCL layer diminishes rapidly with increasing horizontal distance from the cross-passage openings and is unlikely to be necessary beyond the first 3m either side of the openings. This is an important finding because it implies that the tunnel enlargement chambers at cross-passage locations could be reduced in length, leading to safer construction and considerable savings in construction time and cost.

Better design, cost savings, and increased safety through DFOS monitoring

While further research is needed, the results of this investigation indicate significant savings could be made in future designs. Extrapolating the results to the six cross-passage pairs, with three junctions per pair (one for each tunnel) at Liverpool Street, and across the 10 new Crossrail stations, similar projects could potentially save millions of pounds in project costs with the additional benefits of improved safety, reduced carbon emissions and shorter construction times. Similar studies to confirm these findings could result in real savings for comparable projects such as Crossrail 2 and HS2.

Project contact Dr Nicky de Battista, Research Associate, n.debattista@eng.cam.ac.uk